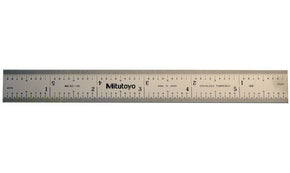

Steel Rules

Steel Rules include precision metal measuring tools essential for accurate dimensional inspection and layout tasks within manufacturing and quality control environments. Designed for applications demanding consistent measurement standards, these tools support processes requiring tight tolerances and repeatability.

Utilizing Steel Rules enhances operational uptime through durable construction and reliable accuracy. They improve workflow efficiency by providing standardized measurements and contribute to workplace safety by minimizing errors in manual dimensions. These instruments also aid in reducing downtime caused by measurement discrepancies.

Key applications:

- Dimensional verification in parts fabrication

- Layout marking and cutting guidance

- Quality assurance inspections and audits

Possible sub-collections: Flexible Steel Rules, Stainless Steel Rules, Industrial Precision Rules.